ASPHALT PAVING EXPERTS

Your #1 Commercial Paving Contractor in Maryland and Virginia

Commercial Asphalt Paving and Repairs

At Aurora Paving and Concrete, we specialize in delivering top-tier solutions for commercial asphalt paving and repairs. With a commitment to excellence and decades of collective experience, we are your trusted partner in ensuring durable and reliable pavement solutions for businesses across Maryland and Virginia! With us we can guarantee:

- Expert Installation: Specializing in new asphalt paving for commercial properties, ensuring durable and functional surfaces.

- Comprehensive Maintenance: Offering extensive repair services from crack sealing to pothole repairs, enhancing pavement longevity.

- Professional Sealcoating: Providing sealcoating and striping services to protect asphalt from elements and improve traffic flow and safety.

THE PAVING PROFESSIONALS

Aurora Paving provides parking lot maintenance solutions for building owners and property managers

For most properties, the parking lot or driveway is a significant investment that helps create a favorable first impression. As commercial property managers have long known, asphalt and concrete maintenance is most cost-effective when approached on a regular basis. Aurora can help correct poor drainage situations, eliminate "trip hazards," help comply with ADA regulations, or simply help enhance your property's curb appeal.

Our approach to business

Once we have determined what you want to accomplish and have inspected the property, we will give you a detailed written proposal that spells out exactly what we will do and the corresponding cost. We don't want you to have any surprises.

Our Guarantee

All of our work is guaranteed for a period of one year from completion for labor and materials. One of our biggest sources of leads comes from referrals.

Affordable, friendly, and PROFESSIONAL

For many, many years, Aurora Paving and Concrete has serviced the Baltimore area and expanded to serve the surrounding areas of Maryland and Virginia. We specialize in asphalt paving, but we also offer services for seal coating, repairs, and more. Our mission is to always provide quality service at an affordable price. We place a high value on client happiness, regardless of the project at hand.

Please feel free to contact us at any time!

COMPlete ASPHALT PAVING, milling, sealing, and more

For many years, Aurora Paving and Concrete has served customers in Maryland and Virginia. Our professional staff can assist you with any paving project, regardless of size, including pavement sealing, lot striping, crack filling, and anything else. Our first focus is ensuring that every client is satisfied, so we always pay close attention to the slightest details. We are a dependable group of contractors who carry the proper licenses and insurance. Call today!

EXCEPTIONAL ASPHALT WORK

Commercial Paving

With our services, you can add to the value of your commercial property with perfectly paved parking lots and more.

PAVEMENT SEALING

With our expert seal coating services for pavement, you can safeguard your asphalt and lengthen its lifespan.

Asphalt repair

We can handle any repair job, no matter how big.

Parking Lot striping

Give your parking lot a fresh look with our striping services.

TOP OF THE LINE COMMERCIAL Concrete Services

Trust us to deliver high-quality workmanship tailored to your specifications, on time, and within budget. Elevate your business environment with our commercial concrete services—where quality meets consistency, and customer satisfaction is our foundation.

PERFECT PARKING LOT Paving & STRIPING

There are numerous reasons why lot striping quality is important. Most significantly, it assures the safety of all visitors to your property. All of the lot striping work performed by Aurora Paving and Concrete complies with Maryland and Virginia requirements based on your location. We take pleasure in offering striping services that are attentive to detail, resulting in a parking lot that is crisp, clean, and well-organized. Impress your customers by hiring our experts to manage your lot striping needs. We provide reasonable prices and high-quality labor, and we always meet deadlines.

Aurora follows the Americans with Disabilities Act (ADA) which mandates that if you provide goods and services to the public (a place of public accommodation), you are required to remove barriers to access when readily achievable. Readily achievable in government-speak means 'easily accomplishable' and 'able to be carried out without much difficulty or expense'. For more information, get in touch with us today!

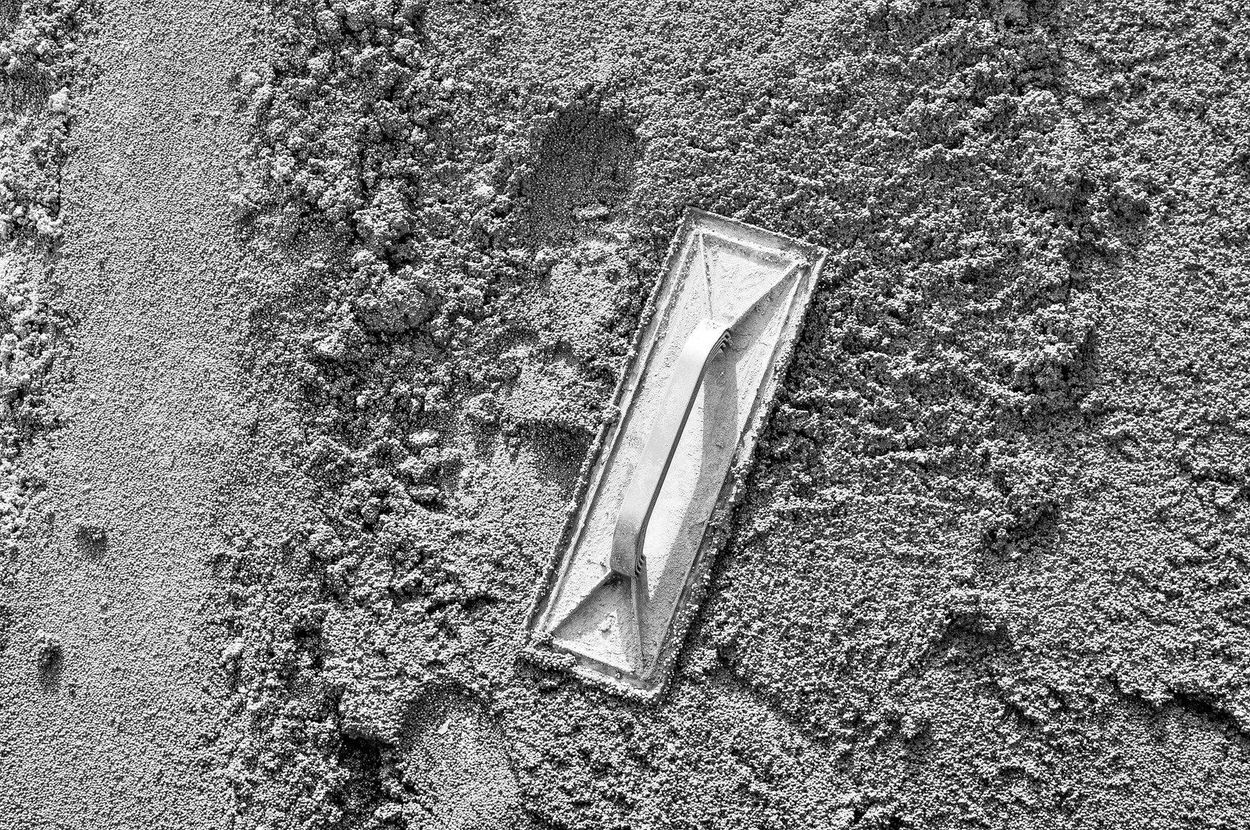

DURABLE asphalt Sealcoating

Sealcoating is a liquid coal tar or asphalt-based sealer that protects asphalt and enhances its appearance. Sealcoating is not a structural repair. In order for sealcoating to do its job, any structural failures or cracks must be repaired in advance. The surface is swept clean, and all dirt, dust and debris are blown off with heavy-duty air blowers. Any severe oil stains are primed with a special bonding agent to allow the sealer to adhere. Next, the sealer is spray applied to the pavement for uniform coverage. The finished result is a jet-black finish that looks great and extends the life of your asphalt. Once your parking lot has been sealcoated, we will re-stripe the parking stalls (including the appropriate handicap stalls) and help restore its curb appeal! Click below to request a free estimate.

Why people believe in us

Frequently Asked Questions

Have a question? We are here to help. Send us a message & we'll be in touch soon.